SHIPMENT OPERATIVE INSTRUCTIONS TO MERLO SPA SITES

This document show the instruction used in Delivery Notes and shipment condition to Goods Reception Service of Merlo SPA.

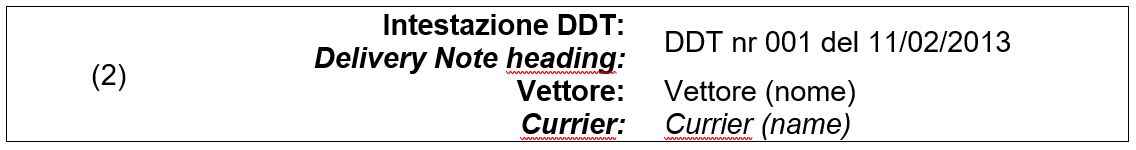

| DELIVERY NOTE |

Delivery Notes must respects here below terms:

1) Every shipment to a Merlo SpA productions sites (as MRL, MRR and MRN) must edit a proper delivery note by following received purchase orders (see below example)

2) Declare Currier name that carry up the goods

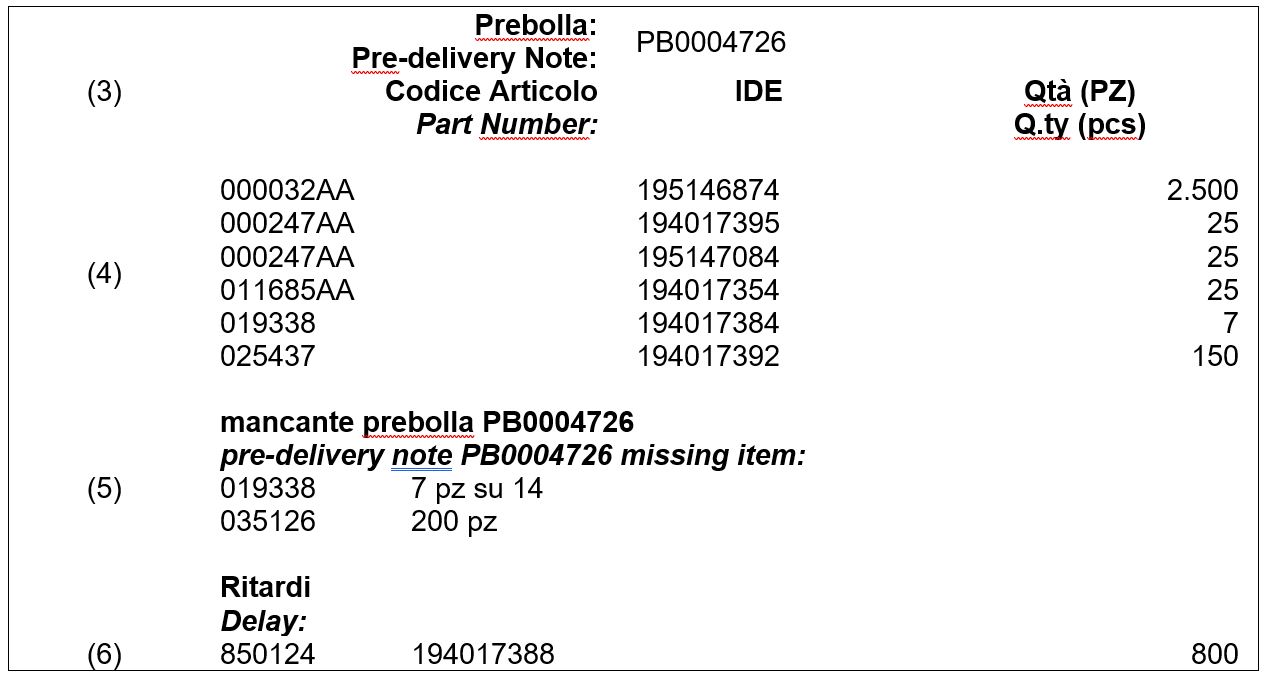

3) Mark pre-delivery note referring code received by our day forecast (*)

4) Mark:

- PURCHASE ORDER NUMBER

- MERLO PART NUMBER

- IDE CODE

- QUANTITY for every Delivery Note row (item purchased in meter/kg but split-up into single unit, as, per instance, coils or pipe, is necessary to mark whether the q.ty in meters/kg that the q.ty in pcs)

- DECLARATION: "SAMPLE COMPONENT FOR MASS PRODUCTION APPROVAL" (only for sampling PO)

5) Mark any missing part number of quantity compared to ordered by pre-delivery note (*)

6) Mark part number, IDE and quantity of former order residual by including at bottom of delivery note and showing as “Ritardi” (*)

7) Report the used packing used by marking part number and quantity

It’s absolutely forbidden:

- to delivery major quantity (even minimal) then delivery schedule (except specific agreement with Merlo SpA Purchase Office)

- to issue more than one Delivery Note for the same delivery (*)

(*) only for Suppliers managed by daily kanban delivery

Example of (daily delivery) Kanban delivery and correct draw-up of the Delivery Note

| COD. PARTE | QTA ORDINE | IDE | Tipo contenitore | Numero contenitori | Sito | Data consegna | Prebolla |

| PART NUMBER | ORDERED QUANTITY | IDE | Packing Type | Number of packing | Site | Delivery Date | Pre-delivery Note |

| 000032AA | 2.500 | 195146874 | 645116 | 5 | MRL | 12/02/2013 | PB0004726 |

| 000247AA | 25 | 194017395 | 645116 | 1 | MRL | 12/02/2013 | PB0004726 |

| 000247AA | 25 | 195147084 | 645116 | 1 | MRL | 12/02/2013 | PB0004726 |

| 011685AA | 25 | 194017354 | 645116 | 1 | MRL | 12/02/2013 | PB0004726 |

| 019338 | 14 | 194017384 | 645117 | 2 | MRL | 12/02/2013 | PB0004726 |

| 025437 | 150 | 194017392 | 645116 | 5 | MRL | 12/02/2013 | PB0004726 |

| 035126 | 200 | 194017404 | 645116 | 2 | MRL | 12/02/2013 | PB0004726 |

| Yellow row: | delivered 7 pz su 14 |

| Red row: | not delivered |

- DDT (Delivery Note)

| GOODS PREPARATION |

Preparation of the goods must follow below rules:

- Identify items and goods by the above mentioned rules join by proper label (and/or by the laber provided within the purchase order and bar code) to recognize every single pack.

If necessary, contact Purchase Office and require bar code system within rolling forecast.

- By the same destination site ( MRL, MRN, MRR ) group to the same pallet.

- Every single packing must clear indicate the contained items (Merlo part number) and, in any case, every single package have to group homogeneous items.

- Keep easily identify sites MRL, MRR and MRN both on load operation into your Plant either in unload operation in Merlo plant, by use an A4 paper on top of every pallets (see below picture)

- How to permit unload operation in Merlo plant, for steel raw materials, must be used only truck with complete openable dumper and removable later/rear banks to carry over the goods in safety way.

(Any exception must be agreed in advance by written with Logistics Manager or Production Plant Manager)

- During the shipment, goods and packing have to be protect from severe weather.

- Any failure to all above instructions will be constitute a non-conformity. Merlo reserves the right to charge the supplier any additional costs arising from this.

THE SUPPLIER SIGNATUREFOR ACCEPTANCE